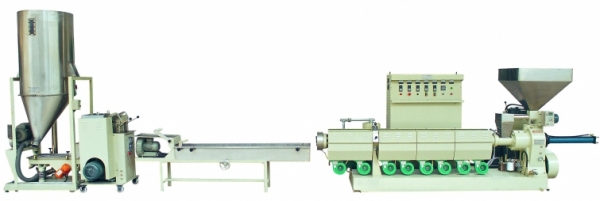

REH : Single screw plastic pelletizing machine

REH : Single screw plastic pelletizing machine

Application:for dyeing and/or recycling of clean rigid thermoplastics, such as ABS, PC, PP, PE, PS, HIPS, PVC, PA, PBT, POM, PET, TPU, TPR, etc.

| Main Technical Data | ||||

| Model No. | REH-60 | REH-80 | REH-110 | REH-125 |

| Output (PC+ABS) | 75~100 Kg/h | 180~280 Kg/h | 320~450 Kg/h | 600~700 Kg/h |

| Install Dimension (M) | 7.5 x 2.2 x 1.8 | 12 x 2.5 x 1.9 | 14 x 3 x 2.2 | 15 x 3.0 x 2.5 |

| Total weight | 2244 Kg | 4400 Kg | 5100 Kg | 6300 Kg |

| (1) MAIN EXTRUDER : | ||||

| Screw dia. | Ø60 | Ø80 | Ø110 | Ø125 |

| L/D ratio | 32:01:00 | 35:01:00 | 33:01:00 | 36~37 : 1 |

| Main motor (AC) | 30HP TECO | 75HP TECO | 125HP TECO | 175HP TECO |

| VF-variable frequency inverter | VF-variable frequency inverter | VF-variable frequency inverter | VF-variable frequency inverter | |

| Gearbox | gear material : 20CrNiMoA / carburizing quenching | |||

| gearbox oil cooling system : heat exchanger/ oil filter system | ||||

| PID thermo controller | 4 Zones | 5 Zones | 7 Zones | 8 Zones |

| Barrel air cooling | 3 sets | 4 sets | 6 sets | 7 sets |

| (auto-start) | (auto-start) | (auto-start) | (auto-start) | |

| Screw material | SACM-645 Nitride treatment, Chrome-plated or SCM-4 bimetallic | |||

| Screen changer | manual or hydraulic | manual or hydraulic | manual or hydraulic | manual or hydraulic |

| Machine size (mm) | 2100 x 1200 x 1500 | 4500 x 1500 x 1600 | 5800 x 1600 x 1600 | 7000 x 1800 x 1700 |

| Machine weight | 1500 Kg | 3500 Kg | 4200 Kg | 5000 Kg |

| (2) ADJUSTABLE SPEED FEEDING HOPPER : | ||||

| Reducer motor | 1/2 HP | 1/2 HP | 1 HP | 1 HP |

| VF inverter driven | VF inverter driven | VF inverter driven | VF inverter driven | |

| reducing ratio | 60:01:00 | 60:01:00 | 30:01:00 | 30:01:00 |

| Screw dia. | Ø70 | Ø70 | Ø94 | Ø94 |

| Hopper capacity | 30~90 Kg | 30~90 Kg | 120~360 Kg | 120~360 Kg |

| Machine size(mm) | 840 x 780 x 850 | 840 x 780 x 850 | 920 x 920 x 800 | 920 x 920 x 800 |

| (3) WATER TANK WITH MOIST SUCKING & BLOWING MOTOR : | ||||

| Sucking motor | 0.75 KW | 1.1 KW | 1.1 KW | 2.2 KW |

| Water tank size(mm) | 3000 x 360 x 220 | 3000 x 360 x 220 | 5000 x 360 x 220 | 5000 x 360 x 220 |

| (4) PELLETS’ CUTTING MACHINE : | ||||

| Motor | 5 HP VS | 10 HP VS | 10 HP VS | 20 HP VS |

| fine tuning control | fine tuning control | fine tuning control | fine tuning control | |

| Rotary cutter | Tungsten steel or SKD-11,18 blades | Tungsten steel or SKD-11,24 blades | Tungsten steel or SKD-11,24 blades | Tungsten steel or SKD-11,28 blades |

| Stationary knife | Tungsten steel | |||

| Machine Size (mm) | 760 x 700 x 1200 | 1000 x 820 x 1230 | 1200 x 1000 x 1300 | 1200 x 1000 x 1300 |

| Machine Weight | 320 Kg | 520 Kg | 890 Kg | 890 Kg |

| *** OTHER OPTIONAL EQUIPMENTS *** | ||||

| (1) HYDRAULIC TYPE AUTOMATIC RELEASE SCREW : | ||||

| Hydraulic press | 3 HP | |||

| (2) MELT PRESSURE INDICATOR : | ||||

| Specification | 0~700 bar pressure range, two-alarm relay | |||

| with high and low peak pressure memory | ||||

| (3) VACUUM DEVICE : | ||||

| Motor / rpm | 3HP / 1750 rpm | 3 HP / 1750 rpm | 5 HP / 1750 rpm | 5 HP / 1750 rpm |

| Liquid sealing volume | 6 liter / min | |||

| (4) VIBRATING PELLET SELECTOR & STORAGE TANK : | ||||

| Vibrating motor | 1/4HP x 2 sets | 1/4HP x 2 sets | 1/4HP x 2 sets | 1/2HP x 2 sets |

| Sieving screen | Upper layer Ø 6mm, Bottom 2mm x 20L / 304# stainless steel | |||

| Storage tank | Volume : 620 liter / 304# stainless steel | |||

| blower motor | 2.2 KW | 2.2 KW | 3 KW | 3 KW |

| Machine size (mm) | 1400 x 1100 x 2800 | 1400 x 1100 x 2800 | 1400 x 1100 x 2800 | 1400 x 1100 x 2800 |

| Machine weight | 270 Kg | 270 Kg | 300 Kg | 300 Kg |

| Patented Product. Imitation Prohibited. | ||||

| Machine's design & specifications subject to change without notice. | ||||